Thin-Gauge Sheet Metal Laser Cutting (0.5–3.0mm) with Fast UK Delivery

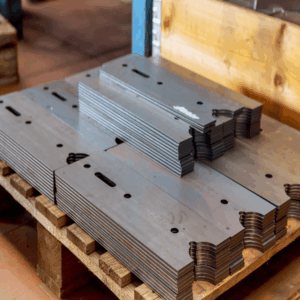

We offer precision thin-gauge sheet metal laser cutting (0.5–3.0mm) with fast UK delivery — covering aluminium, steel, brass, copper and more. Our service is provided through MS Laser Services Ltd, located next door to Metal Offcuts. By combining our in-house metal stock with on-site laser cutting, you get accurately cut parts, quick turnaround, and competitive pricing from a single supplier.

Laser Cutting — thin-gauge sheet metal parts in aluminium, copper, brass, zinc, stainless & mild steel.

Whether you need a small one-off job, a prototype part or larger production runs, we offer affordable pricing, fast turnaround and expert cutting across our full range of sheet metals.

Laser Cutting for One-Offs, Prototypes & Small Batches

Metal Offcuts is ideal for one-off parts and small batch laser cutting. Because we stock a wide range of metals in thin-gauge sheet, you don’t need to buy full sheets just to test a design.

- One-off laser cut parts – perfect for jigs, brackets, plates and custom pieces.

- Prototype sheet metal parts – trial designs before committing to larger runs.

- Small production batches – repeatable sizes, clean edges and consistent quality.

- Use our stock or your own material – we can cut from Metal Offcuts sheet or free-issue metal.

You only pay for the sheet and a simple cutting charge, making it cost-effective for small jobs and trials.

Laser Cut Circles, Discs & Custom Shapes

Thin-gauge laser cutting is ideal for circles, discs and non-standard shapes that are difficult to produce accurately with hand tools.

We regularly cut:

- Metal discs and circles for bases, signs, flanges and jigs.

- Rounded rectangles and radiused panels for guards, covers and plates.

- Slots, holes and cut-outs for fixings, cable entries and fixtures.

- Decorative shapes and panels for craft, signage and interiors.

We also specialise in precise laser cutting for custom parts including bespoke stainless steel mirrors, where accuracy, edge quality and repeatability are essential.

Why Choose Our Laser Cutting Sheet Metal Service?

- Thin-gauge specialists – focused on 0.5–3.0mm sheet metal for accurate, clean cutting.

- Competitive prices for small jobs – use Metal Offcuts stock and pay a simple cutting charge.

- Bulk orders welcome – full sheets and production runs supplied within our group.

- Fast turnaround – laser cutting machine on-site at MS Laser Services, next door to our warehouse.

- Wide range of metals – copper, brass, zinc, aluminium, stainless steel, mild steel and Corten.

- Additional processes available – guillotine cutting, light fabrication and welding where required.

Trusted by trade customers, designers and manufacturers across the UK, we supply precision-cut parts from our Merseyside base to customers in Liverpool, the North West and nationwide.

Metal Offcuts Proud Members of Made in Britain

Materials & Thickness – What We Cut

We specialise in laser cutting a wide range of sheet metals in thin gauges. Below are the typical thicknesses we work with:

- Aluminium: 0.5mm to 3.0mm

- Stainless Steel: 0.5mm to 3.0mm

- Brass, Copper & Zinc: 0.7mm to 3.0mm

- Mild Steel: 1.0mm to 3.0mm

If you require something outside these ranges, get in touch — we may still be able to help or suggest alternatives.

How Our Laser Cutting Sheet Metal Process Works

- Send us your job details – ideally in DXF format for quicker processing.

- Need a CAD drawing? We can create one for a small charge from sketches or basic dimensions.

- We cut your parts using our high-precision fibre laser and prepare them for dispatch or collection.

Getting your parts laser cut is straightforward – simply send your DXF file or drawing and we’ll take care of the rest.

If you don’t have a file, we offer CAD drawing services to ensure your part is accurately designed before cutting.

Learn more about how laser cutting works and what you can create with it in our

Custom Laser Cutting for Sheet Metal Guide.

Additional Services: Guillotine Cutting & Fabrication

Some projects need more than one process. Working within the Metal Sheets group, we can also offer:

- Guillotine cutting – fast, straight cuts and batch processing of panels and strips.

- Fabrication & welding – basic fabrication on sheet metal components where required.

- Mixed process orders – jobs combining laser cutting and guillotining handled under one roof.

Whether you need one-off parts, prototypes or ongoing production batches, we have the tools and expertise to support your project.

Get a Laser Cutting Quote Today

Contact us today for a free laser cutting quote

For a fast and competitive price, send your job details to sales@metaloffcuts.co.uk

or call 0151 526 4777.

We’re ready to assist you with precision sheet metal laser cutting at great prices – from one-off parts and prototypes to regular trade supply.

About MS Laser Services Ltd

MS Laser Services Ltd is a group company of Metal Sheets Ltd, providing high-precision thin-gauge sheet metal laser cutting. Located next door to Metal Offcuts, it gives our customers direct access to:

- Thin-gauge specialist laser cutting (0.5–3.0mm)

- Fast UK-wide delivery on cut parts and panels

- Seamless supply – metal stock, cutting and dispatch all coordinated within the group

Visit mslaserservices.co.uk to learn more.

Laser Cutting FAQs

Do you laser cut one-off parts and prototypes?

Yes. There is no minimum order quantity – we’re happy to help with one-off prototypes, samples and test parts.

Simply send your file or sketch and we’ll quote based on material and cutting time.

Can you laser cut metal circles and discs?

Yes. Laser cutting is ideal for metal circles, discs and rounded shapes, especially in thin-gauge sheet. We can cut discs in

aluminium, stainless steel, brass, copper and mild steel within our typical thickness range.

What types of cutting do you offer?

We offer both fibre laser cutting for intricate, detailed shapes and guillotine cutting for straight edges.

Our laser is ideal for precision parts, signage and complex designs, while guillotine cutting suits fast, straight trims.

Do you supply the sheet metal or just offer a cutting service?

We supply and cut sheet metal in-house. Choose from aluminium, copper, brass, zinc, stainless steel and mild steel — all available in a variety of thicknesses and finishes. You can also send your own material for cutting if preferred.

What file formats do you accept for laser cutting?

We recommend DXF or DWG files for precision cutting. However, we can also work with AI, SVG, PDF or even hand-drawn sketches — our team can convert them into laser-ready files if needed.

What are your minimum and maximum thicknesses?

We specialise in cutting thin-gauge sheet metals from 0.5mm to 3.0mm thick. This includes brass, copper, aluminium, zinc, stainless steel and mild steel.

For thicker materials or special requirements, please contact us.

How quickly can you turn around an order?

Standard lead times are typically 2–4 working days, depending on the material, volume and complexity. Larger or more detailed projects may take longer — we’ll confirm the turnaround time when we quote.

Is there a minimum order quantity?

No minimum quantity is required — we’re happy to help with one-off prototypes, small batches or ongoing trade supply. Just send us your design or enquiry and we’ll take it from there.

Can I visit your facility or speak to someone about my project?

Yes. We welcome customer enquiries and visits by appointment. Feel free to contact us to discuss your project with our team — we’re always happy to help with advice or technical queries.

Do you offer finishing services after cutting?

Yes, we offer light deburring and cleaning after laser cutting. For additional services like patination, polishing or lacquering (especially for signage or decorative work), please get in touch — we may be able to assist through our partner companies.

What industries do you work with?

We work with designers, engineers, interior fit-out companies, signage makers, furniture brands and more. Whether you’re an individual or a business, we can assist with everything from concept to finished components.